Policies

Contents

Copyright Notice

Content

External Sites

Notification on Freight Charges

Pricing and Availability

Colour or Product Substitutions

Method of Payment

Using Website Information

Copyright Notice

All site design, text, graphics, interfaces and the selection and arrangement thereof are protected by copyrights owned by Gemtex Holdings Pty Ltd. ALL RIGHTS ARE RESERVED TO Gemtex Holdings Pty Ltd. Permission is granted solely to electronically copy and to print in hard copy portions of this site for the sole purpose of placing an order with Fastmag or using this site as a shopping or information resource. Any other use of materials on this site, including reproduction for purposes other than those noted above, modification, distribution or republication, without the prior written permission of Gemtex Holdings Pty Ltd is strictly prohibited.

Content

Gemtex Holdings Pty Ltd trading as Fastmag has endeavoured to ensure that all information contained in this Web site at the time of publishing is accurate and accept no responsibilities for any inaccuracies that may have occurred. All services, specials, colours, products and prices are subject to change or cancellation without prior notice. Whilst every care is taken in preparing this website, the services referred to in this site are offered to the customers and members without any liability whatsoever being incurred on the part of Gemtex Holdings Pty Ltd trading as Fastmag, or its associated companies. Members choosing to enter into arrangements with the companies and firms offered, do so entirely at their own judgment and consideration.

External Sites

This site may contain links to other sites on the Internet that are owned and operated by third parties. Gemtex Holdings Pty Ltd makes no claim or representation and accepts no responsibility regarding the quality, nature, or reliability of the sites, products or information accessible by hyperlinks from this website, or sites linking to this website. The site administrator or webmaster for those sites should be contacted if you have concerns regarding such links or the content located on such sites.

Notification on Freight Charges

- We include an automatically applied freight charge in our shopping cart. These freight charges and options are displayed prior to committing to the purchase.

Pricing and Availability

Price and availability is subject to change without notice. You will of course be provided current prices at the time you place your order.

Color or Product Substitutions

If you specify a color, or product that is not in stock when we receive your order, you will receive an email giving you the choice of selecting a different color or product, or waiting until your chosen color or product is available.

Method of Payment

We accept, Visa, Master Card, and American Express.

Using Website Information

This site contains information about activities and products. Since each person’s circumstances are different, Gemtex Holdings Pty Ltd trading as Fastmag and Fastmag cannot be responsible, and cannot assume any liability for the use of such information. Information obtained from this site should be used only after you have considered your specific situation and assessed the risks involved.

Freight

All freight is calculated in our Shopping Cart and the net cost can be viewed prior to submitting your order.

Regular Delivery.

Allow approximately 3 to 5 working days for regular delivery via Australia Post or a local courier service, this can change if the destination postcode is in a distant regional area.

Express Delivery.

We endeavour to despatch all our express orders within 24 hours ( excluding weekends and public holidays ) and while most parcels are delivered very quickly, Australia Post do not have a blanket delivery guarantee for all postcodes in Australia, and sometimes during busy periods the delivery delays can happen for no apparent reason, regardless of postcode, and Australia Post do not give meaningful explanations.

Magnetic Sheeting Cutting Service

Fastmag offer a cutting service on their range of flexible magnetic sheeting and striping products. When you require a custom sized sheet, label, or sign, please contact Mike to discuss your requirements and receive a quote for that special application. We do not have any minimum order requirements and our cutting charges are very competative, so we look forward to hearing from you.

Typical sizing & uses for a cut magnetic sheet:

| Description | Size | Details |

| Pallet Racking label | 50mm x 100mm | 0.6mm or 0.9mm thick white magnet |

| Magnetic Car Sign | 300mm x 60mm | 0.9mm thick white magnet |

| Whiteboard Magnets | 25mm x 60mm | 0.6mm or 0.9mm thick white magnet |

| Pad Holder | 25mm x 90mm | 0.6mm or 0.9mm thick self adhesive magnet |

| Coaches Sports Board | 20mm x 75mm | 0.6mm or 0.9mm thick white magnet |

Magnetic Handling Instructions

Flexible Magnetic Rolls and Sheeting

Magnetic Sheeting is manufactured from synthetic rubber with ferrite powder added. The sheeting is only magnetised on one side, the other side is either plain or laminated with self adhesive, white or coloured vinyl.

Magnetic Sheeting is typically available with a self adhesive or coloured vinyl finish. The adhesive finish enables you to permanently adhere the magnet sheet to many different flat surfaces. The white vinyl finish can be written on with a marker (e.g. warehouse stock label), silk screened to produce a fridge magnet or apply self adhesive vinyl signage to make say a magnetic car sign.

Magnetic Tabs (Mag Tabs)

These are small rectangular magnets 20mm x 40mm which have a peel off adhesive back (Peel & Stick) that are ideal for attaching to business cards, calendars, posters, photos, and any number of non-magnetic items to fridges or any similar metallic surface with magnet adhering properties.

Neodymium (Rare Earth) Magnets

Discs, Rods, Cylinders, Blocks and Shallow Pots

Rare Earth magnets are magnets that are made of the Rare Earth group of elements. The most common Rare Earth magnets are the Neodymium-Iron-Boron and Samarium Cobalt types.

The most powerful magnets available today are the Rare Earths. Of the Rare Earths, Neodymium-Iron-Boron types are the strongest. However, at elevated temperatures (of approximately 150C and above), the Samarium Cobalt types can be stronger that the Neodymium-Iron-Boron types (depending on the magnetic circuit).

Neodymium magnets manufactured from sintered neodymium iron boron possess the most powerful magnetic properties in relation to volume and can lift 1000 times its own weight. However these magnets do not possess heat resistant qualities and usually remain stable in temperatures up to 80 C. For higher temperature applications, Rare Earth or Samarium Cobalt is recommended. Also due to the corrosive nature of this material, Neodymium is usually supplied nickel coated. These magnets are usually magnetised through the thickness, and are often used when space is limited and you need a lot of sticking power. Neodymium Magnets or Rare Earth magnets can be used for demonstrating attraction and repulsion, for science, engineering, research and development, education, industry, and magic.

Hard Neodymium discs, blocks or rings are sold individually and the uses are endless. Well, apart from having numerous industrial uses, these magnets can be used for just about anything where a strong magnet is required.

Note: The larger of these magnets are exceptionally strong and should be used with caution.

Ferrite Magnets

Discs, Rods, Cylinders, Blocks, and Shallow Pots

Ferrite Magnets are manufactured from Strontium, usually die pressed and sintered. Sintering is when a mass of metal particles are bonded and partly fused by the use of pressure and heat below melting point. Due to good machining properties these magnets can be cut and magnetised to virtually any size of shape required. And the high coercively and low cost are the reason these magnets are used in a wide range of applications. Stable up to a maximum temperature of 120 C, these magnets by weight are stronger than steel. Like all ceramics these magnets are quite brittle and will easily break if dropped onto a hard surface. However these magnets are the most economical choice for magnetic strength.

Ferrite Magnets manufactured by die pressing and are a low cost effective solution to many applications where high resistance to de-magnetism and high working temperature is required. Ferrite Magnets have moderate strength and are not subject to oxidation when used in harsh environments. Hard Ferrite Magnets have Inherent high coercive forces and high remanence after magnetization insuring product stability over a wide range of operating conditions. Ferrite magnets are grey in colour and are have either an Anisotropic or Isotropic orientation. Frequently used in electric motors, separators, speakers, therapy, craft, material handling etc.

Most modern magnet materials have a “grain” in that they can be magnetized for maximum effect only through one direction. This is the “orientation direction”, also known as the “easy axis”, or “axis”. Un-oriented magnets (also known as “Isotropic magnets”) are much weaker than oriented magnets, and can be magnetized in any direction. Oriented magnets (also known as “Anisotropic magnets”) are not the same in every direction – they have a preferred direction in which they should be magnetized.

Magnet Types

Ferrite or Ceramic Magnets

Ferrite Magnets or Ceramic Ferrite Magnets are manufactured from strontium ferrite, usually die pressed and sintered. Sintering is when a mass of metal particles bonded and partly fused by the use of pressure and heat below the melting point. Due to good machining properties, these magnets can be cut and magnetized to virtually any size or shape required. Due to their high coercively and low cost, they are used in a wide range of applications. Stable up to a maximum temperature of 250°C, by weight they are stronger than steel, but less so than neodymium or Rare Earth Magnets. Like all ceramics, they are quite brittle and will easily break if dropped onto a hard surface. They are the most economical choice for magnetic strength.

These magnets are also made in different grades. Ceramic-1 is an isotropic grade with equal magnetic properties in all directions. Ceramic grades 5 and 8 are anisotropic grades. Anisotropic magnets are magnetized in the direction of pressing. The anisotropic method delivers the highest energy product among ceramic magnets at values up to 3.5 MGOe (Mega Gauss Oersted). Ceramic magnets have a good balance of magnetic strength, resistance to demagnetizing and economy. They are the most widely used magnets today.

Ferrite magnets are generally the best choice for doing repulsion and attraction experiments since some of the rare earth magnets may be too strong and bar magnets will demagnetize. Ferrites come in blocks/slabs, disks and rings.

Attributes of Ceramic Magnets

High intrinsic coercive force.

Least expensive material compared to alnico and rare earth magnets.

Limited to simple shapes due to manufacturing process.

Lower service temperature than alnico, greater than rare earth.

Finishing requires diamond cutting or grinding wheel.

Lower energy product than alnico and rare earth magnets.

Rare Earth Magnets or Neodymium Iron Boron Magnets

Neodymium Magnets or Rare Earth Magnets are manufactured from sintered neodymium iron boron. They possess the most powerful magnetic properties in relation to volume and can lift up to 1000 times their own weight. However they do not possess strong heat resistant qualities usually remaining stable up to 80°C, although SH grades of the compound are available which are stable up to 120°C. For higher temperature applications, rare earth samarium cobalt is recommended. Also due to their corrosive nature, neodymium is usually supplied nickel coated. These magnets are magnetized through their thickness, and are often used when space is limited and you need a lot of sticking power. Neodymium Magnets or Rare Earth Magnets can be used for demonstrating attraction and repulsion, for science, engineering, research & development, education, industry and magic, but the larger ones are exceptionally strong and should be used with caution.

Neodymium Magnets or Rare Earth Magnets are available in disks, slabs/blocks, and rings.

What is the difference between Ferrite Magnets and Rare Earth or Neodymium Magnets?

The biggest differences between ferrite magnets and rare earth magnets is that rare earth magnets are much stronger. The intensity of magnetization and the coercive force are elements determining the performance of permanent magnets. Since rare earth magnets contain iron and cobalt in the state not containing oxygen, their magnetization is large. In addition, magnetization of rare earth magnets has a strong force (coercive force) aligning the magnetism in one direction, so they are much stronger magnets than ferrite magnets. Since they have about seven (7) times the performance of ferrite magnets in total energy per volume, rare earth magnets are used for powerful magnetic circuits that could not be conceived of until now, space-saving magnetic circuits, etc.

What are the primary applications for Rare Earth or Neodymium Magnets?

The primary application, for rare earth magnets, is the voice coil motors that are a part of computer hard disk drives. Other applications include various industrial motors, sensors, consumer electronics, office equipment, musical instruments, and cellular phones. Recently, rare earth magnets have been used in products that help protect the environment and save energy such as electric vehicle motors, wind powered generators, and air conditioner compressors.

Attributes of Rare Earth or Neodymium Magnets

Very high resistance to demagnetization

High energy for size

Good in ambient temperature

Moderately priced

Material is corrosive and should be coated for long term maximum energy output

Low working temperature for heat applications, but higher levels of heat resistance materials are being introduced periodically.

Bar & Horse Shoe Magnets

Bar Magnets are used in physics education labs to show magnetic fields when used with compasses, iron filings or light metal objects such as paper clips. If a bar magnet or horseshoe magnet is stored properly, with its keepers, it can have a shelf life of at least 20 years.

Flexible Magnets

Flexible magnets are very similar to the injection moulded magnets but are produced in flat strips and sheets. These magnets are lower in magnetic strength and very flexible depending on the materials that was used in the compound with the magnetic powders. Vinyl is often used in this type of magnet as the binder.

Magnetic Pole Patterns

Typical Magnetization Patterns

Oriented (anisotropic): has better magnetic properties in a given direction. During the manufacturing process, a magnetic field is applied in the direction of preferred magnetization to orient the material and increase the magnets performance potential. With oriented material, multiple pole magnetization flux goes through the magnet making both sides of the magnet strong.

Non-oriented (isotropic): Has equal magnetic properties in all directions. During the manufacturing process the magnet is not exposed to a magnetic field. This material can be magnetized in any magnetization pattern. This material is weaker than oriented materials. With non-oriented material, multiple pole magnetization flux bends inside the magnet making it strong on one side only.

The following magnetization patterns apply to both oriented and non-oriented magnet materials.

The following magnetization patterns apply to both oriented and non-oriented magnet materials.

Bars

Through the length – Magnetized North at one end and South at the other.

Rods

Through the length or axial – Magnetized North on one end and South on the other.

Blocks

Through the thickness – Magnetized North on one side of the thickness and South on the other.

Disc or Ring

Through the thickness – Magnetized North on one face of the disc and South on the other.

Bar or Block

Through the width or across the width – Magnetized North on one side of width and South on the other.

Discs

Multiple poles (two sets or more) on a surface magnetized through the thickness – Magnetized with more than one set of N/S poles on one or both faces of the magnet.

Flexible Magnetic Pole Patterns

Flexible Magnetic Pole Patterns

(A) Conventional Magnetization: has one pole on each side of the magnet. North pole on one side, South pole on the other.

(B) Multiple Pole (Standard)

(B1) Two Poles.

(B2) Multiple Poles on each side; two or more sets of poles on each surface are used in open circuit designs. North and South poles alternate through the thickness of the material. Steel backing is desirable where practical.

Gauss Strength

Gauss strength is measure of magnetism named after the German mathematician Karl Friedrich Gauss ( 1777 to 1855 ), who applied mathematical principles to magnetism.

Gauss rating determines the speed at which a magnet works

The thickness determines the magnet depth of penetration

The gauss rating of a magnet determines the speed in which it works, and the thickness determines the depth of penetration. Some magnet companies list their products by internal gauss, not the external gauss rating. A quick rule of thumb in determining proper gauss strength is take the external gauss rating and multiply this number by 3.9. So, a 600 gauss external strength rated magnet can also be called a 2,340 gauss internal strength rated magnet. It is important that you are not misled into believing you’re getting a higher strength product, as both are correct ratings for the same magnet.

Gauss strength can be misleading

Gauss strength can be misleading, as the strength of the magnetic field falls off very quickly as the distance from the surface of the magnet increases. In clinical use, depending upon the strength, size, and distance from the skin, actual gauss strength inside the human tissue can be much less than the gauss rating of the magnet. If the magnet is to penetrate deep into the body, it will need to be stronger. To act one inch deep, it should be a 700 to 1000 gauss external strength rated magnet. For two inches deep a 1200 to 2000 gauss external strength rated magnet is best.

The material of a magnet alone does not determine its strength

It is important to note that the material of a magnet alone does not determine its strength. It is a combination of material (strength) and mass (size). To illustrate, lets take one neodymium magnet (12,000 gauss) and one ceramic magnet (4,000 gauss). If both magnets are the same size, the neodymium will have the stronger field, because it has a larger gauss rating.

Now let’s assume that the same neodymium magnet has a 1/2″ diameter and 1/8″ thickness, and the ceramic magnet a 3/4″ diameter and 1/4″ thickness. Even though the neodymium magnet is rated 12,000 gauss and the ceramic is 4,000 gauss, the ceramic magnet will have the stronger field. Why? Because, its greater mass helps to produce a stronger field.

In most clinical studies the best results are achieved with a magnetic field of 500 to 600 gauss within the tissue, which often requires a much stronger magnet to deliver that amount of energy within the body itself. The depth of penetration of the magnetic field appears to be at least as important as its strength. This is extremely important. The larger the mass of the magnet, the stronger and more effective it will be. If the magnets are too small, the magnetic field will drop below therapeutic levels before it even reaches the injury site. Magnets made from Neodymium (a rare earth metal), commonly called Rare Earth Magnets, are unusually strong in relation to their size, and therefore believed to have the deepest penetrating fields. Some people may have a skin reaction to direct exposure to some Rare Earth Magnets. For this reason, many therapeutic magnets are plated with gold or other non-reactive metal, or contained within a wrap or magnetic mattress pad.

Gauss strength is not cumulative

Something else to be aware of is that gauss strength is not cumulative. In other words if each magnet has a manufacturers gauss rating of 3,000 and there are 10 magnets in the product, the strength is still 3,000 gauss, NOT 30,000 gauss. Although, more magnets in a products means that the magnets are spaced closer together, creating a more uniform magnetic field. The number of magnets needed to create a consistent field is also dependent upon the size of the magnets. As stated previously, larger magnets will create larger fields. The key is that you do not want large spaces between the magnets, as large spaces will create empty gaps in the magnetic field, in which there is no therapeutic benefit.

Note: If you come across a product that simply states gauss strength without stating that it is the surface or external rating, divide the value of the product by 3.9. For example a 10,500 manufacturers rating for a neodymium magnet, will measure approximately 2,690 surface gauss using a digital gauss meter (which is a very accurate instrument).

Choice of Magnet

It is for these reasons that Fastmag in mentioning Gauss levels realise it can lead to a lot of confusion and incorrect assumptions as to what makes a good choice of magnet for any purpose. However, we can personally guarantee that we have the best magnet type, and quantity of magnets for your purpose, and if seeking more information we are here to assist.

The Hysteresis Loop

A great deal of information can be learned about the magnetic properties of a material by studying its hysteresis loop. A hysteresis loop shows the relationship between the induced magnetic flux density (B) and the magnetizing force (H). It is often referred to as the B-H loop. An example hysteresis loop is shown below.

The loop is generated by measuring the magnetic flux of a ferromagnetic material while the magnetizing force is changed. A ferromagnetic material that has never been previously magnetized or has been thoroughly demagnetized will follow the dashed line as H is increased. As the line demonstrates, the greater the amount of current applied (H+), the stronger the magnetic field in the component (B+). At point “a” almost all of the magnetic domains are aligned and an additional increase in the magnetizing force will produce very little increase in magnetic flux. The material has reached the point of magnetic saturation. When H is reduced to zero, the curve will move from point “a” to point “b.” At this point, it can be seen that some magnetic flux remains in the material even though the magnetizing force is zero. This is referred to as the point of retentivity on the graph and indicates the remanence or level of residual magnetism in the material. (Some of the magnetic domains remain aligned but some have lost their alignment.) As the magnetizing force is reversed, the curve moves to point “c”, where the flux has been reduced to zero. This is called the point of coercivity on the curve. (The reversed magnetizing force has flipped enough of the domains so that the net flux within the material is zero.) The force required to remove the residual magnetism from the material is called the coercive force or coercivity of the material.

As the magnetizing force is increased in the negative direction, the material will again become magnetically saturated but in the opposite direction (point “d”). Reducing H to zero brings the curve to point “e.” It will have a level of residual magnetism equal to that achieved in the other direction. Increasing H back in the positive direction will return B to zero. Notice that the curve did not return to the origin of the graph because some force is required to remove the residual magnetism. The curve will take a different path from point “f” back to the saturation point where it with complete the loop.

From the hysteresis loop, a number of primary magnetic properties of a material can be determined.

Retentivity – A measure of the residual flux density corresponding to the saturation induction of a magnetic material. In other words, it is a material’s ability to retain a certain amount of residual magnetic field when the magnetizing force is removed after achieving saturation. (The value of B at point b on the hysteresis curve.)

Residual Magnetism or Residual Flux – the magnetic flux density that remains in a material when the magnetizing force is zero. Note that residual magnetism and retentivity are the same when the material has been magnetized to the saturation point. However, the level of residual magnetism may be lower than the retentivity value when the magnetizing force did not reach the saturation level.

Coercive Force – The amount of reverse magnetic field which must be applied to a magnetic material to make the magnetic flux return to zero. (The value of H at point c on the hysteresis curve.

Permeability – A property of a material that describes the ease with which a magnetic flux is established in the component. Reluctance – Is the opposition that a ferromagnetic material shows to the establishment of a magnetic field. Reluctance is analogous to the resistance in an electrical circuit.

Magnetic Characteristics

There are two kinds of magnets, isotropic and anisotropic.

Isotropic

This is a magnet whose crystal grains do not have their easy magnetization axis lined up in a specific direction and whose magnetic characteristic is isotropic. Isotropic magnets include bond magnets using quick-cooled thin alloy as the raw material and isotropic ferrite magnets, but their magnetic characteristics are inferior to those of anisotropic magnets.

Rare Earth sintered magnets can not be made isotropic.

Anisotropic

A magnet whose crystal grain directions are aligned and have their easy magnetization axis lined up is called an anisotropic magnet.

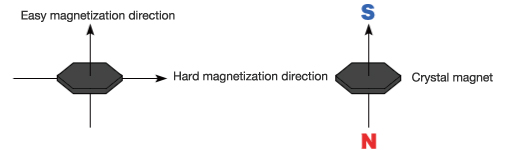

Ferrite Crystal and Easy Magnetization Direction

The shape of a ferrite crystal is similar to a short hexagonal prism. By magnetizing in the direction of the prism height, a strong magnet can be made.

Crystal Arrangement of an Isotropic Magnet

The crystal direction and arrangement of isotropic crystals are various, so a magnet with the same strength can be made by magnetizing from any arrow direction.

The crystal direction and arrangement of isotropic crystals are various, so a magnet with the same strength can be made by magnetizing from any arrow direction.

Crystal Arrangement of an Anisotropic Magnet

The crystal direction and arrangement of anisotropic crystals are unidirectional in the easy magnetization direction, so a strong magnet can be made only by magnetizing from the easy magnetization direction of the arrow.

The crystal direction and arrangement of anisotropic crystals are unidirectional in the easy magnetization direction, so a strong magnet can be made only by magnetizing from the easy magnetization direction of the arrow.

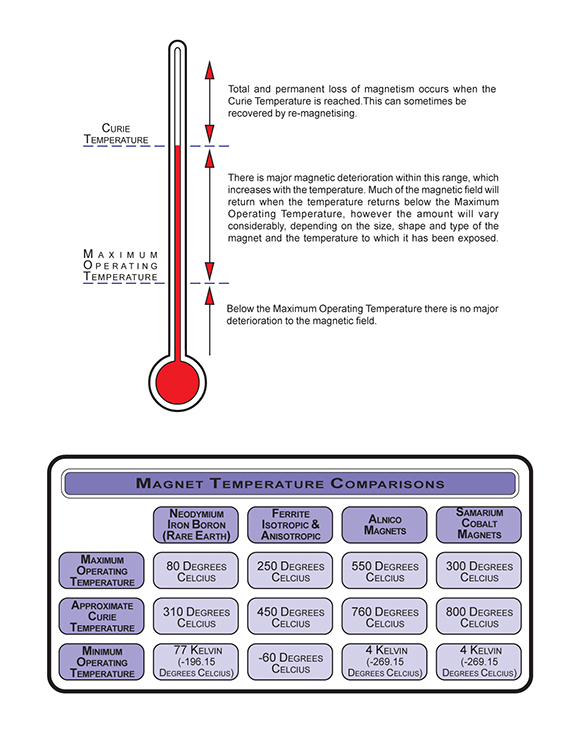

The General Effect of High Temperature on Magnets

Sustainable Magnet Temperature

Cooling

Neodymium magnets are not damaged by immersion in liquid nitrogen at a temperature of -196°C (77K). These magnets can be used without hesitation for superconductor experiments.

Ferrite Magnets lose part of their magnetisation permanently at a temperature below -40°C.

Magnetic Strips and Magnetic Sheets lose part of their magnetisation permanently at temperatures below -20°C. Temperatures under -20°C and above 80°C damages the structurual integrity of magnetic tapes and sheets. It causes the products to permanently lose part of their adhesive force. Therefore, do not use these in places with extremely high or low temperatures.

Therefore, Ferrite Magents, Magnetic Strips, and Magnetic Sheets should not be vigorously cooled.

Heating

Neodymium magnets of the type N lose part of their magnetisation permanently at a temperatures at and above 80 °C, strips and sheets at 80 °C, and ferrite magnets at 250°C.

If you heat a magnet above its “Maximum Working Temperature”, it loses part of its magnetisation, and at the “Curie Temperature”, there is no remanence of magnetisim left.

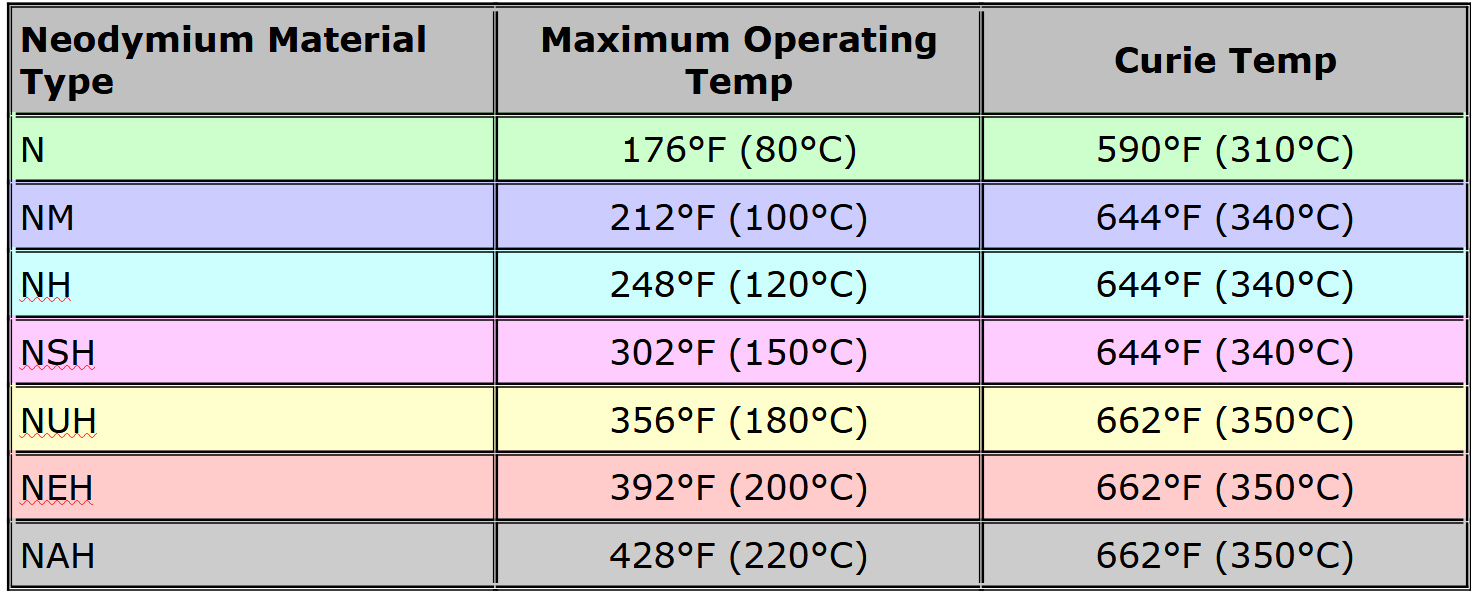

Thermal Grades

The thermal characteristics listed below are values commonly associated with each magnets Grade for example: N42SH means this Neodymium magnet has a strength grade of 42 and the SH refers to the increased temperature operating range of…. MOT 150c – Curie 340c for this particular magnet, for a standard N42 magnet this Max operating range would be a slighly lower MOT 80c – Curie 310c.

Airfreighting Magnets

Tips for Safely Airfreighting Magnets

Magnets are generally considered dangerous goods, which can only be forwarded by airfreight under certain circumstances. Correct classification requires accurate measurements, which FASTMAG cannot provide.

When in doubt, we recommend avoiding airfreight.

According to IATA (International Air Transport Association) Packing Guideline 953 (formerly 902), a shipment with magnets falls under one of three categories:

1. Airfreight Forbidden (magnetic field too large)

If the package with the magnets (including magnetic shielding packaging) creates a magnetic field of more than 0,00525 gauss (=5,25 mG = 0,525 µT) at a distance of 4,6 metres (in any direction), the transport of the package via air freight is generally forbidden.

2. Airfreight Unproblematic (magnetic field very small)

The second and more strict test requires that at a distance of 2,1 metres from the package a magnetic field of less than 0,002 gauss (2 mG = 0,2 µT) is created.

If the package passes this test, the content is considered “not magnetised” for transport purposes and the package can be shipped. In that case it is recommended to attach a shipping declaration that confirms that the package passed the stricter test and therefore can be viewed as non-magnetic. This can avoid possible delays due to inspections by authorities.

3. Airfreight Declared as Dangerous Goods (for all other cases)

If the package falls between the two categories, meaning the first test was passed but not the stricter second one, the package has to be declared a dangerous good, which will lead to higher shipping costs and additional work. Also, there are certain airports that cannot be used in this case.

The aim is, therefore, to pass the stricter second test and airfreight the package without special measures.

The big problem with this packing regulation lies in the fact that this measurement can only be done with expensive special equipment. Most magnetic field measuring devices cannot measure such weak magnetic fields.

A correct classification requires accurate measurements, which Fastmag cannot provide. When in doubt, we recommend to stay away from airfreight.

If the shipment is not airfreight (train, truck, ship, etc.), magnets are not considered dangerous goods.

Airfreight Neodymium Magnets

Neodymium magnets create a far-reaching and strong magnetic field. The mandatory tests have to be carried out accurately to avoid endangerment and monetary fines from the aeronautical authority.

Airfreight Ferrite Magnets

Ferrite magnets create a much weaker magnetic field than neodymium magnets. Therefore, it takes less effort to pass the mandatory tests.

Airfreight Magnetic Sheets, Magnetic Strips

Sheets, tapes and C-profiles produce a clearly weaker magnetic field than neodymium magnets. Therefore, they pass the required tests much easier.

Shipping

Mailing

Yes, if you package them appropriately. You have the following options:

- Arrange magnets antiparallel

- Increase the distance between magnets and package

- Shield magnets with iron sheets

If you airfreight the package, you need to adhere to strict rules. See airfreight.

If you send the package with regular mail, the rules of the postal service apply, which are different in every country. Some don’t even have regulations regarding the shipment of magnets.

Nevertheless, we recommend considering a few rules, since improper packaging can lead to shipping problems. You could damage items in other packages (credit cards, hard discs, monitors, etc.) or cause disruptions with the sorting machines of the postal service. Your package could also get caught on a metal piece and content could be pulled out.

To avoid such damages you should package the magnets appropriately for shipping. You have three possibilities that you can apply separately or combined:

1. Arrangement of Magnets

If you send several magnets together you can massively reduce the magnetic field through the proper arrangement of magnets within the package. Two or more magnets should be arranged in a way that half of the magnets are parallel to the other half, the poles pointing in opposite directions.

For instance, if you want to send 50 disc magnets with a diameter of 10 mm and a height of 3 mm, these basically arrange themselves into a “bar” of 50 x 3 = 150 mm length. However, you should not ship this bar like that, but break it up in the middle, so that the north poles of 25 magnets point into one direction and the other half lays parallel to them, but with the north pole pointing in the other direction. This way, the magnets will be “short circuited” and the magnetic field of the package will be almost zero. Naturally, you can arrange four, six or more “bars” parallel to each other.

If you only have 2 magnets to send, it is possible that this arrangement is not stable, meaning that the magnets don’t want to stay in this anti-parallel position. You can arrange the magnets on a piece of metal sheet – one magnet with its north pole towards the metal sheet, the other one with its south pole towards the metal sheet. This way, the magnets can be stabilised and the magnetic “short circuit” is even better with the metal sheet, meaning the magnetic field will decrease massively.

Several sphere magnets can be arranged in a circle in order to neutralise the magnetic field.

The goal of the arrangement has to be that, if possible, the same amount of north poles and south poles of the individual magnets point into one direction.

2. Create Distance

The magnetic field of a magnet decreases with increasing distance very quickly. Therefore, it is advisable to pack a rather big package and position the magnets in the middle of it. It doesn’t matter if you fill up the space with paper, Styrofoam, bubble wrap, cardboard or wood. Except for sheet steel, other materials are no barriers for magnetic fields. Only the increased distance is responsible for the reduction of the magnetic field. Of course, you’ll have to retain the magnets in the middle of the package, so they won’t travel towards the sides of the package during the course of the transport.

Therefore, the shipping of bigger magnets in an envelope is not advisable, since the distance to the outer surface is too small.

3. Shielding with Sheet Steel

If the “cheaper” methods of neutralisation or oversized packaging are not sufficient, you are left with utilising sheet steel for shielding. Sheet steel can be bent around a big magnet. It is not necessary that the sheet and the magnet touch each other, but it is important that the sheet steel induces a “short circuit”, meaning that it reaches from the north pole to the south pole of the magnet. If you only place a sheet on the north pole and another one at the south pole and the sheets are not connected, this doesn’t produce any shielding. The ideal shielding constitutes a box of sheet steel that totally encompasses the magnet. The stronger the magnet and the more complete the shielding should be, the thicker the sheet steel would have to be, so it does not reach a magnetic saturation and can induce a “magnetic short circuit”.

Paper Clip Test

In order to check if a package is not overly magnetic, its surfaces would have to be measured with a teslameter and an acceptable critical value would have to be determined. This is often not possible. An every-day-life test is the paper clip test: You put a paper clip to all sides of the package and it should not stick, but fall down. If you want to be even stricter, you can hold the surface not upright but at an angle of e.g. 45 degrees and see if the paper clip slides over the entire surface. If this test is successful, you should not have any problems during transport and the package should arrive safely without getting caught or damaging other items.

Shipping of Different Magnet Types

During transport, these minimum distances between the different magnet types need to be observed to prevent damages and mutual demagnetisation – Neodymium and Ferrite Magnets 22mm.

Swallowing

Children could swallow small magnets.

If several magnets are swallowed, they could get stuck in the intestine and cause perilous complications.

Magnets are not toys! Make sure that children don’t play with magnets.

Electrical Conductivity

Magnets are made of metal and conduct electricity.

Children might try to put magnets into a power outlet and thereby suffer from an electric shock.

Magnets are not toys! Make sure that children don’t play with magnets.

Contusions

Big magnets have a very strong attractive force.

- Unsafe handling could cause jamming of fingers or skin in between magnets. This may lead to contusions and bruises.

- Powerful, very large magnets could cause bone fractures.

Wear heavy protective gloves when handling larger magnets.

Pacemaker

Magnets could affect the functioning of pacemakers and implanted heart defibrillators.

- A pacemaker could switch into test mode and cause illness.

- A heart defibrillator may stop working.

- If you wear these devices keep a safe sufficient distance to magnets.

- Warn others who wear these devices from getting too close to magnets.

Heavy Objects

Too heavy loads, symptoms of fatigue as well as material defect could cause a magnet or magnetic hook to loosen from the surface that is was attached to.

Falling objects could lead to serious injuries.

- The indicated adhesive force applies only to ideal conditions. Allow for a high safety cushion.

- Don’t use magnets in places where people could sustain injuries in case of material failure.

Metal splinters

Neodymium magnets are brittle. Colliding magnets could crack.

Sharp splinters could be catapulted away for several meters and injure your eyes.

- Avoid the collision of magnets.

- Wear safety glasses when handling larger magnets.

- Make sure that nearby people are also protected or keep their distance.

Magnetic field

Magnets produce a far-reaching, strong magnetic field. They could damage TVs and laptops, computer hard drives, credit and ATM cards, data storage media, mechanical watches, hearing aids and speakers.

- Keep magnets away from devices and objects that could be damaged by strong magnetic fields.

- Please refer to safety sufficient distance.

Combustibility

When machining magnets, the drilling dust could easily ignite.

Stay away from machining magnets or use appropriate tools and sufficient cooling water.

Nickel allergy

Many of our magnets have coatings that contain nickel.

- Some people have an allergic reaction when they come into contact with nickel.

- Nickel allergies could develop from constant contact with nickel-plated objects.

- Avoid constant skin contact with nickel-plated magnets.

- Avoid contact with magnets if you already have a nickel allergy.

Nickel allergy

Many of our magnets have coatings that contain nickel.

- Some people have an allergic reaction when they come into contact with nickel.

- Nickel allergies could develop from constant contact with nickel-plated objects.

- Avoid constant skin contact with nickel-plated magnets.

- Avoid contact with magnets if you already have a nickel allergy.

Airfreight

Magnetic fields of improperly packaged magnets could influence airplane navigation devices, in the worst case it could lead to an accident.

- Airfreight magnets only in packaging with sufficient magnetic shielding.

- Please refer to the respective regulations.

Postage

Magnetic fields of improperly packaged magnets could cause disturbances in sorting machines and damage fragile goods in other packages.

- Please refer to our shipping tips.

- Use a large box and place the magnet in the middle surrounded by lots of padding material.

- Arrange magnets in a package in a way that the magnetic fields neutralise each other.

- If necessary, use sheet iron to shield the magnetic field.

- There are stricter rules for airfreight: Refer to the warning notice “Airfreight”.

Influence on People

According to the current level of knowledge, magnetic fields of permanent magnets do not have a measurable positive or negative influence on people. It is unlikely that permanent magnets constitute a health risk, but it cannot be ruled out entirely.

- For your own safety, avoid constant contact with magnets.

- Store large magnets at least one metre away from your body.

Splintering of coating

Most of our neodymium magnets have a thin nickel-copper-nickel coating to protect them from erosion. This coating could splinter or crack due to collision or large pressure. This makes them vulnerable to environmental influences like moisture and they could oxidise.

- Separate big magnets, especially spheres, with a piece of cardboard.

- Avoid collisions of magnets as well as repeated mechanical exposure (e.g. blows, bashes).

Oxidation, Corrosion, Rust

Untreated neodymium magnets oxidise quickly and disintegrate.

Most of our magnets have a nickel-copper-nickel coating to protect them from corrosion. This coating provides some protection against corrosion, but it is not robust enough for continuous outdoor use.

- Use magnets only in the dry indoors or protect them against environmental influences.

- Avoid damages to the coating.

Temperature Resistance

Neodymium magnets have a maximum working temperature of 80 to 200 °C.

Most neodymium magnets lose part of their adhesive force permanently at a temperature of 80 °C.

- Don’t use magnets in places where they are exposed to extreme heat.

- If you use an adhesive, don’t harden it with hot air.

Mechanical Treatment

Neodymium magnets are brittle, heat-sensitive and oxidise easily.

- When drilling or sawing a magnet with improper tools, the magnet may break.

- The emerging heat may demagnetise the magnet.

- The magnet will oxidise and disintegrate due to the damaged coating.

Stay away from mechanical treatment of magnets if you do not possess the necessary equipment and experience.

Tips for Safe Handling

Swallowing

Children could swallow small magnets.

If several magnets are swallowed, they could get stuck in the intestine and cause perilous complications.

Magnets are not toys! Make sure that children don’t play with magnets.

Contusions

Big magnets have a very strong attractive force.

Unsafe handling could cause jamming of fingers or skin in between magnets. This may lead to contusions and bruises.

Wear heavy protective gloves when handling larger magnets.

Pacemaker

Magnets could affect the functioning of pacemakers and implanted heart defibrillators.

- A pacemaker could switch into test mode and cause illness.

- A heart defibrillator may stop working.

- If you wear these devices keep sufficient distance to magnets.

- Warn others who wear these devices from getting too close to magnets.

Heavy objects

Too heavy loads, symptoms of fatigue as well as material defect could cause a magnet or magnetic hook to loosen from the surface that is was attached to.

Falling objects could lead to serious injuries.

- The indicated adhesive force applies only to ideal conditions. Allow for a high safety cushion.

- Don’t use magnets in places where people could sustain injuries in case of material failure.

Magnetic field

Magnets produce a far-reaching, strong magnetic field. They could damage TVs and laptops, computer hard drives, credit and ATM cards, data storage media, mechanical watches, hearing aids and speakers.

- Keep magnets away from devices and objects that could be damaged by strong magnetic fields.

- Please refer to safety sufficient distances.

Airfreight

Magnetic fields of improperly packaged magnets could influence airplane navigation devices.

In the worst case it could lead to an accident.

- Airfreight magnets only in packaging with sufficient magnetic shielding.

- Please refer to the respective regulations.

Postage

Magnetic fields of improperly packaged magnets could cause disturbances in sorting machines and damage fragile goods in other packages.

- Please refer to our shipping tips.

- Use a large box and place the magnet in the middle surrounded by lots of padding material.

- Arrange magnets in a package in a way that the magnetic fields neutralise each other.

- If necessary, use sheet iron to shield the magnetic field.

- There are stricter rules for airfreight: Refer to the warning notice “Airfreight”.

Demagnetisation through neodymium magnets

Stronger neodymium magnets can cause a change of magnetisation direction or demagnetisation in ferrite magnets.

Store ferrite magnets at least 5 cm away from neodymium magnets and do not mix those types of magnets.

Temperature resistance

Ferrite magnets can be used at temperatures between -40 °C and 250 °C.

At lower and higher temperatures they lose part of their adhesive force permanently.

Don’t use ferrite magnets in places where they are exposed to temperatures below -40 °C or above 250 °C.

Mechanical treatment

Ferrite magnets are brittle.

When drilling or sawing a magnet with improper tools, the magnet may break.

Stay away from mechanical treatment of magnets if you do not possess the necessary equipment and experience.

Influence on people

According to the current level of knowledge, magnetic fields of permanent magnets do not have a measurable positive or negative influence on people. It is unlikely that permanent magnets constitute a health risk, but it cannot be ruled out entirely.

- For your own safety, avoid constant contact with magnets.

- Store large magnets at least one metre away from your body.

Information about individual devices and dangers

Magnetic Card

There are expensive and cheaper versions when it comes to cards with magnetic stripes (“magnetic cards”).

High-quality magnetic stripes can be found on credit or ATM cards. They are dark-brown or black and it takes 0,4 tesla (0,4 tesla = 400 mT = 4000 gauss) to demagnetise these cards. But already a third of this field strength is enough to partially delete magnetic stripes so that they can’t be properly read anymore. At a tenth of the demagnetisation field strength (coercive field strength), meaning 40 mT, there is no danger of damages anymore.

Cheaper magnetic stripes are light-brown and frequently used on parking garage or admission tickets. These stripes are much more sensitive. It takes only 30 mT to demagentise these cards. Field strengths of up to 3 mT certainly do not cause any harm.

Pacemaker and Heart Defibrillator

A pacemaker or heart defibrillator is implanted in people with heart rhythm disturbances. These devices are implanted under the skin in the chest area. They produce electrical impulses, which regulate the activity of the heart, if the patient’s body cannot produce these regular impulses itself anymore or if cardiac fibrillation occurs.

A static magnetic field can cause pacemakers and heart defibrillators to switch into special mode. The characteristics of special mode can be programmed and are determined by the manufacturer. A physician can initiate a controlled switch into special mode with a strong permanent magnet. He does that to;

- Control pacemaker and heart defibrillator

- Set a determined frequency for some cycles (independent from the actual need of the body)

- Disable certain functions of the defibrillator

As soon as the magnet is removed, the pacemaker or heart defibrillator starts working normally again.

Newer pacemakers switch into special mode at 1 mT, older models already at 0,5 mT (=5 gauss). Therefore, you need to adhere to the safe distances to permanent magnets outlined in the table above.

However, we cannot offer you a magnet that can purposefully switch a pacemaker into special mode, since this depends on the device and is beyond our knowledge as a magnet retailer.

Mechanical Watch

A strong magnetic field can magnetise parts of mechanical watches, like for instance the spiral spring. The parts then react to other steel parts in the clockwork or to the clock case. This may lead to the watch being fast or slow.

Most of the standard watches now follow the ISO 764 standard and are “non-magnetic”. Such watches need to be able to resist a magnetic field of 60 gauss (=6 mT), which means that after being exposed to this magnetic field they can only be off by a maximum of 30 seconds per day. Some manufacturer offer especially designed non-magnetic watches that can withstand up to 1,000 gauss.

It is difficult to indicate a safe distance for non-magnetic watches. If you want to be on the safe side, you should keep as much distance for the magnetic field to equate only to the natural Earth’s magnetic field of about 0,05 mT.

If a mechanical watch was magnetised by accident and doesn’t work properly anymore, you can bring it to a watch maker. He can demagnetise it with a special demagnetisation device, which creates an alternating magnetic field.

Analogue quartz watches can be disturbed by a strong magnet, because the strong magnetic field interferes with the motor. They might all of a sudden be fast, slow or stop working altogether. But as soon as the magnet is removed and the time is corrected, the quartz watch should be working normal again.

Hearing Aid

The following components of modern hearing aids may react to static magnetic fields:

- The speakers

- The coils responsible for the wireless communication between two hearing aids or between hearing aid and remote control

A magnetic field strength of 200 mT or above can cause permanent damage.

A magnetic field strength from 20 to 200 mT can cause temporary malfunction which may include:

- Distorted acoustic signal

- Strongly reduced remote control reach

- Collapse of the bidirectional radio link hearing aid or hearing aid accessory

Vehicle Key

A static magnetic field does not damage a vehicle key or the embedded transponder for the anti-theft device. Therefore, you can hang up your vehicle key on a magnetic board.

USB Stick, Memory Cards (Compact Flash, Secure Digital, etc.)

USB sticks and memory cards are not magnetic data carriers and will therefore not be damaged by static magnetic fields.

Digital Camera, Cell Phone, iPhone, iPod, iPad etc.

Cameras, cell phones and smart phones contain non-magnetic storage media. Therefore, static magnetic fields near those devices cannot delete data.

There are countless covers with magnetic closures or magnetic holders on the market, which also speaks against the notion that magnets can damage these devices.

However, it cannot be ruled out that very strong magnetic fields might magnetise and maybe damage mechanical parts or built-in speakers. When in doubt, keep these devices away from strong magnets.

CD, DVD

CDs and DVDs sticks are not magnetic data carriers and will therefore not be damaged by static magnetic fields.

Hard Drive

You can find much contradictory information regarding this topic. Hard drive manufacturers themselves don’t like to talk about it. But generally, hard drives are much more resistant to big magnets than expected. The hard drive coating usually provides a high level of coercivity. This means you would have to bring a very large magnet very close to a hard drive in order to delete files. As long as you don’t unscrew the top cover of the hard drive, you won’t be able to get close enough. A strong magnetic field, however, can damage mechanical components of the hard drive. A magnet can, for instance;

- block the motor of the reading head

- influence the position of the writing head or

- damage the writing head

All the above may lead to irreparable damages.

Hard drive of a desktop computer: A magnet is hardly a danger for hard drives embedded in a desktop computer, because you cannot get close enough. Compact laptop hard drives, however, which are generally located near the bottom plate, are more sensitive towards permanent magnets. We cannot provide safe distances due to insufficient data and differing construction of hard drives, but even our biggest magnets should not be able to damage a hard drive at a distance of 20 cm.

Intentional deleting: If you plan on deleting data on a hard drive permanently, using a permanent magnet is not a suitable method. You can use special file deletion software, which overwrites the hard drive multiple times

Understanding the Gauss Measurement

We’re often asked if a magnet “has 10,000 Gauss” which is not a simple question to answer, since Gauss is a unit of magnetism that can apply to different measurements or magnet properties. A magnet doesn’t have one specific measure of Gauss and the two common measurements expressed in Gauss are the Residual Flux Density, Br, and the Surface Field.

Residual Flux Density, Br, is the magnetic induction remaining in a saturated magnetic material after the magnetizing field has been removed. The Br value is measured under closed circuit conditions. A closed circuit condition exists wherein a magnetized permanent magnet is working by itself with no high permeability material, which is usually pure iron or low carbon steel. This means the air gap for the magnetic circuit is limitlessly large, and this number is a material property which is independent of the magnet shape. Grade N42 magnets have a Br of 13,200 Gauss, while N52 magnets can be as high as 14,800 Gauss.

The Surface Field is the strength of the magnetic field measured right at the surface of the magnet. It’s the field strength measured on a magnetometer’s sensor hard up against the surface of the magnet. The open circuit (not attached to any other ferrous object) surface Gauss value is the density of the magnetic field at any point on the surface of the magnet, and will depend on the magnet material, the shape of the magnet and how it’s used in a magnetic circuit.

For example, a 25mm diameter by 20mm thick N52 neodymium magnet, made from the strongest magnetic material commercially available will measure a maximum of 6,250 Gauss on the magnet’s surface.

Note; Magnets in open circuit conditions rarely exceed a value of 7,000 Gauss.

The actual measurement will depend on whether the magnet has any steel attached to it, how far away from the surface you make the measurement, and the size of the magnet (assuming that the measurement is being made at room temperature). For example, a 1″ diameter N-48 Neo magnet that is 1/4″long, will measure approximately 2,800 Gauss 1/16″ away from the surface, and 2,466 Gauss 1/8″ away from the surface, and then considerably less as you move the magnet away from the surface.

Caution

Whilst Fastmag do not sell Magnetic Therapy products, we recommend that the use of all magnetic therapy products should be discontinued for people with pace makers, nursing mothers, and also during pregnancy.

Magnets are capable of erasing the information stored on Computer Disks, Video Tapes, Audio Tapes, Credit, Debit Cards, and can also cause damage to Television Screens, and other sensitive equipment. Please do not place magnetic products on or near any of the above.

Keep Rare Earth Magnets or Neodymium Magnets away from small children, two magnets can snap together so quickly they will break a finger, and when swallowed can cause severe medical complications.

Rare Earth Magnets or Neodymium Magnets are very brittle, do not allow two to come close without maintaining a very secure grip since they can leap out of your hand, snap together and shatter causing risk of damage to the eyes.

Guarantee

The Fastmag product is guaranteed for a period of 12 months from the date of purchase against faulty materials and workmanship, provided that is used for the purpose intended by the manufacturer and it is stored and used in the recommended manner. This guarantee does not apply to any defect, deterioration. loss, injury or damage occasioned by, or as a result of the misuse or abuse of this product and is limited to the making good of the product by either repair or replacement at the manufacturers discretion. This guarantee is not inclusive of any transportation of the product and is valid only if the product is delivered to manufacturers premises.